TECH4EFFECT final event highlights research impacts

The T4E project held its final event in June signalling the end of the joint Horizon2020/BBI JU funded project which brought together a consortium of 21 partners across eight countries and three continents.

The main goal of the project has been to contribute to knowledge-based management in forestry for increasing production and environmental efficiency in wood procurement. Improved efficiency and reduced environmental impacts in forest management are considered to contribute to an overall improvement of the environmental and socio-economic performance of the full value chain.

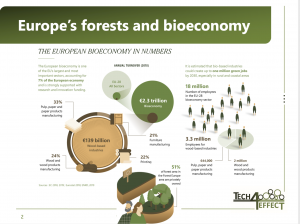

In terms of wood procurement, Europe’s forests hold a considerable potential to meet the European bioeconomy’s increasing demand for raw materials for the production of bio-based materials, products, chemicals and energy. Moving away from fossil-based resources and materials to create viable alternatives is part of the European Green Deal aiming at net zero pollution targets by 2050.

Courtesy of the European Forest Institute (EFI).

“There is still an additional potential of more than 200 million (m) cubic metres of timber on top of the current volumes that can be harvested within the framework of good and sustainable forest management. That is, if appropriate technologies, silvicultural and harvesting systems are used.” — Diana Tuomasjukka, Work Package Leader of Impact Assessment from the European Forest Institute.

Mobilising wood for the European bioeconomy

The mobilising of wood resources can be challenging for many reasons due to varying resource availability, terrain characteristics, public opinion across Europe, and the lack of suitable weather conditions for harvesting with minimum impact to the ground, or simply because of low profit margins in supply operations due to decreasing revenues and increasing costs.

“I don’t need to stress the importance of forests to sustain biodiversity, provide valuable biological renewable resources, maintain the health of soil and air, capture CO2 and fight climate change. Sustainable forest management is therefore a fundamental topic that underlies many of the current world challenges.” — BBI JU Project Officer TECH4EFFECT, Pilar Llorente, opening the TECH4EFFECT final event.

TECH4EFFECT has investigated a large variety of measures to enhance access to wood resources, and to increase the production and environmental efficiency of timber harvesting and extraction. TECH4FFECT has made significant progress not by single large leaps, but by the sum of incremental improvements along the whole supply chain.

Key research results

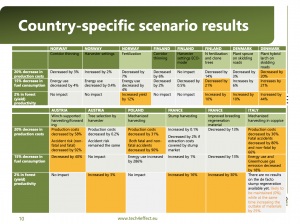

Courtesy Diana Tuomasjukka, EFI.

From a research point of view, TECH4EFFECT has advanced the field in many respects both in relation to technical improvements and in furthering the development of digital tools for improvements in environmental and production efficiency. Due to its timing in a period of increasingly rapid development in the field of digitalisation, TECH4EFFECT also marks a transitional phase between classic and new data acquisition and analysis methods.

Novel, first-ever results

Some examples include the first-ever overview of cable yarder manufacturers’ experience in flat, impassable terrain, thus identifying future R&D needs leading to the investigation of the overall technology for more safe and environmentally sound cable harvesting using the so-called double-hitch carriages.

Many of the results achieved across the project will be featured in a TECH4EFFECT Special Issue in the International Journal of Forest Engineering due to be published in the second half of 2021.

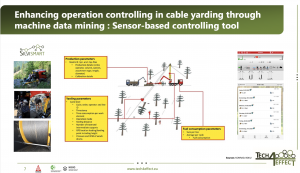

Courtesy Gernot Erber, BOKU.

Another research and industry collaboration first includes machine data and analysis and real-time controlling of harvesting operations that offer considerable potential for increasing efficiency and output in cable yarding timber harvesting in mountainous terrain. This machine data potential has not been previously developed in cable yarding. Within T4E, an all-new machine data management system for cable yarders was developed in association with project partner Konrad Forsttechnik GmbH, which can be fed into the TECH4EFFECT SILVISMART efficiency portal in the future.

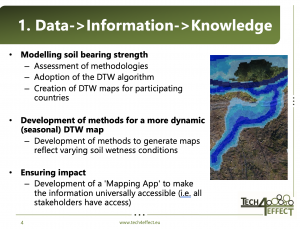

Courtesy of Bruce Talbot, NIBIO.

Research also pointed to the future potential of using meteorological systems to better predict the bearing capacity of roads, potentially avoiding road damage and saving considerable sums otherwise used on rehabilitation. With regard to the bearing capacity of forest soils and the avoidance of damage there, the Depth-to-Water (DTW) algorithm developed by Murphy et al. (2011; 2009; 2007) was further elaborated on and implemented in the research. A promising approach for verifying DTW maps and how the mapping represents soil moisture and bearing capacity was developed. Also, the accuracy of DTW maps and how well they correspond with actual wheel rutting was also tested.

Courtesy of Bruce Talbot, NIBIO.

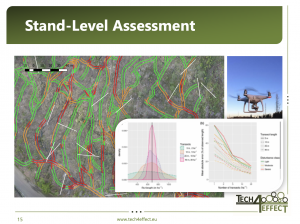

Additionally, a novel methodology was developed to measure soil disturbance in the form of wheel ruts using drones. The developed method is much more efficient and provides soil disturbance overviews with much less effort and less error than the current manual measurements. Overall, TECH4EFFECT has shown how drones can be used as an important tool both in research and daily operations.

TECH4EFFECT scientific and industry authors contributed a comprehensive report titled Increasing access to wood resources which examined 12 cases for a potential increase in forestry mechanization across seven countries in Europe, also focusing on an increase in growth rates in forests and to achieve measurable improvements in efficient forest operations.

Key Exploitable Results

Other key exploitable results included the SILVISMART efficiency portals, a benchmarking algorithm, the Tracking App, TECH4EFFECT Mapping App, the TECH4EFFECT Bucking App, performance of the winch-assisted forwarder, recommendations on fuel savings, in association with Ponsse, and issues arising from the policy brief. These results will provide a solid basis for furthering the knowledge-based component of the project in the form of research and innovation between scientists and industry, especially in the field of increased forestry digitalization.

“From my personal perspective I think that when the sawmill industry is using digitalisation and the forestry industry is not using digitalisation, then we have a big problem. I think that in 10 years digitalisation will change forestry dramatically, and am 100 per cent convinced of that.” — Karl Stampfer, Professor and Head, Department of Forest and Soil Sciences, Head Institute of Forest Engineering, University of Natural Resources and Life Sciences (BOKU), Vienna answering a question on the future of forestry digitalization.

Courtesy of NIBIO.

TECH4EFFECT Co-ordinating partner, the Norwegian Institute of Bioeconomy Research (NIBIO), Division of Forest and Forest Resources, as owner of SILVISMART, will continue its work on the development of the SILVISMART digital platform which will utilize research from across many of its projects, including that of T4E. In October 2020, the NIBIO Division of Forest and Forest Resources was awarded state-funding of 234 million Norwegian krone (EUR23.4m) for the establishment of SmartForest4.0 which will continue to work towards Industry4.0 over a period of eight years ending in 2028.

“We currently have all the enabling technologies, like forest harvesters, that collect vast amounts of data, and if we combine that with digital tools and analytics we can get to innovation and efficiency gains within this sector. Of course, that will also come with some changes to the sector, like the creation of new business models. This will be good for some forest actors and less good for others, nonetheless digitalisation will be an ongoing process.” — Rasmus Astrup, T4E Co-ordinator and Head of Research from the Division of Forest and Forest Operations, Norwegian Institute of Bioeconomy and Research.

Panel Discussion

Antti Asikainen, Professor in Forest Technology and Executive Vice-President for Research, Natural Resources Institute Finland (LUKE), seen commenting here on one of the sometimes diverging opinions expressed by the participants.

The TECH4EFFECT open online event, due to the Corona virus pandemic, culminated in a panel discussion where some of Europe’s leading forest engineers and researchers lent their views to issues such as the availability and accessibility of forest resources. This is in an era of increased climate change impacts that have strengthened the European political will to deliver more stringent laws regarding the protection of forests and access restrictions due to biodiversity considerations.

“We look at the new EU regulations and we see that there is the EU bio-diversity strategy which is promoting 30 per cent of land to be protected and 10 per cent strictly protected, which means that there will be no timber harvesting allowed in these areas. And then we have the climate protection laws, and at least in Germany, the country will aim for another percentage of protected forest, and when you relate that to climate change disturbances, like drought and beetle infestations, we have a lot of softwood forest stand loss which is now being substituted by hardwood, with a completely different form of utilization. So, I think resource availability will be an issue of the future.” — Dirk Jaeger, Professor and Head of Department of the George-August University of Göttingen, Faculty of Forest Sciences and Forest Ecology, Burckhardt Institute, answering a question on the major challenges for a sustained increase in wood supply from Europe’s forest regions.

Issues that were highlighted in the panel discussion included: the challenges for a sustained increase in wood supply, especially in steep and impassable terrain; accessing forest resources in difficult to access terrain, including a move towards mechanised operations to improve the safety of people in the workplace; the establishment and maintenance of an adequate forest road network to access European resources in an environmentally considered and well managed way; reducing the occupational stress factors that mechanised forest machine operators are subjected to, including an ageing workforce that has led to a global shortage of machine operators; and finally the outlook for the increased digitalisation of forestry, including the potential of machine data mining across the sector, also for robotics.

“At the moment, the experiment with robotic machines have found that they can locate themselves really accurately, they can see the surroundings both visually and with sensors such as laser scanners, and they can also sense the soil and the orientation of the machine very well. The challenge still lies in dealing with highly variable harvesting conditions, as well as seasonal differences including snow, rain, and darkness and also being able to operate as these conditions vary within the course of a day. Then, of course, you would need to organise the maintenance and the relocation of machines. So, technology is approaching that level, but the question is when the technology would become competitive.” — Antti Asikainen, Professor in Forest Technology and Executive Vice-President for Research, Natural Resources Institute Finland (LUKE) answering a question on the future of robotics and automated machines in forestry.

Key interactive Mentimeter questions drove the dialogue that leant towards an increase in the degree of digitalisation and mechanisation in precision forestry for increasing efficiency and safety. Mechanised forest harvesters collect vast amounts of data and if this data were combined with digital tools and analytics, vast improvements could be made concerning forest-sector innovation and best practice.

“I think we will see an increase in digitalization and that it will become an important factor in forestry and also in Italian forestry. Many contractors already use digital tools to a limited extent, but when the tools become more contractor-adapted, then they will take it up immediately. My idea is that maybe we need to study the contractors and their needs a bit more.” — Raffaele Spinelli, prolific scientific publisher and researcher at the Italian National Research Council, CNR IVALSA, Institute of Bioeconomy.

This project has received funding from the Bio Based Industries Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement No 720757.