2021

2021 Productivity, fuel consumption and cost in whole tree cable yarding: conventional diesel carriage versus electrical energy-recuperating carriage

Thomas Varch, Gernot Erber, Raffaele Spinelli, Natascia Magagnotti & Karl Stampfer

“Productivity, fuel consumption and cost in whole tree cable yarding: conventional diesel carriage versus electrical energy-recuperating carriage”

International Journal of Forest Engineering Nov, 2020

Abstract:Cable yarding is an inherently expensive extraction technology, but the mainstay for mountain forest management. Fuel cost represents a considerable share of total harvesting costs. Energy-recuperating, electrical slack-pulling carriages (EC), which recuperate energy during lateral yarding and store it as electrical energy in super-capacitors for powering slack-pulling during the subsequent yarding cycle have emerged only recently. Fuel consumption of cable yarding is expected to be lower when ECs are employed compared to working with conventional, diesel engine-powered slack-pulling drive (DC) carriages. To determine if reality matched expectations, a time and motion study was conductedduring which fuel consumption was extracted from the engine control systems using custom-made dataloggers for an uphill whole tree yarding operation in Austria. Average productivity was 21.9 m3 per productive system hour excluding delays (m3 PSH0−1) at 0.89 m3 average tree volume and 58.4 m average yarding distance. Productivity was modeled as a function of average tree volume, yarding distance and lateral yarding distance. Average fuel consumption was 1.27 ± 0.97 l m−3 (DC) and 0.88 ± 0.56 l m−3 (EC). In the DC treatment, the carriage engine accounted for 9% of the total fuel consumption. Modeling revealed that fuel consumption depended on average tree volume, yarding distance, lateral yarding distance and carriage type as originally postulated. The latter effect interacted with that of average tree volume and EC’s advantage in fuel consumption was limited by a break-even average tree volume. In conclusion, the EC has the potential to improve profit margins in small-tree operations through lower fuel consumption.

Download PDF of here. DOI: https://doi.org/10.1080/14942119.2020.1848178

2021 Does Juvenile Stand Management Matter? Regional Scenarios of the Long-Term Effects on Wood Production

Haikarainen, S.; Huuskonen, S.; Ahtikoski, A.; Lehtonen, M.; Salminen, H.; Siipilehto, J.; Korhonen, K.T.; Hynynen, J.; Routa, J.

“Does Juvenile Stand Management Matter? Regional Scenarios of the Long-Term Effects on Wood Production”

Forests 2021, 12(1), 84

Abstract: We analysed the regional level effects of juvenile stand management (early cleaning and precommercial thinning), shortly termed tending on wood production and the profitability of forest management. Altogether ca. 0.4 million hectares of juvenile stands from two significant forestry regions of Finland, South and North Savo, were examined. We used plot-level data of the 11th National Forest Inventory to represent the current status of juvenile stands in the study area, and the Motti stand simulator to predict the future developments of those stands for the next 100 years. We applied three scenarios: (i) Timely tending, (ii) delayed tending, and (iii) no tending, to examine differences between these alternative levels of juvenile stand management. The results showed the benefits of tending at a regional level. Timely tending was the most profitable option when low or modest interest rates (2–3%) were applied in the assessment. Even a short delay in tending clearly increased the tending costs. Delaying and neglecting tending resulted in significant losses, especially in sawlog removals and stumpage earnings. The financial gain from tending was the highest on fertile sites. Due to the high growth rate of trees, the situation may change very quickly on such sites. For the operational forestry, this means that fertile sites should have a high priority when conducting timely tendings.

Download PDF of here. DOI: https://doi.org/10.3390/f12010084

2021 The effect of partial automation on the productivity and cost of a mobile tower yarder

Spinelli R., Visser R., Magagnotti N., Lombardini C., Ottaviani G., 2021.

“The effect of partial automation on the productivity and cost of a mobile tower yarder”

Abstract: Integration of technology is commonplace in forestry equipment supporting higher levels of automation and efficiency. For technology adoption to be successful it must demonstrate improvement in productivity, cost–effectiveness or in human factors and ergonomics. Cable yarding lends itself to automation with repetitive machine movement along a fixed corridor, as established by the skyline. This study aimed at investigating the difference in productivity between the two possible settings (manual and automated) of a Valentini V850 yarder equipped with automatic path programming, with a Bergwald 3-t carriage and radio controlled chokers. The study took place in the northern Italian Alpine eastern region over a period of 8 days on two separate corridors, resulting in 280 measured cycles split between manual and automated. Results in terms of absolute numbers were very close for the two system options, but significant differences were found. For example, inhaul time was longer, but outhaul time shorter for the automated system. Productivity ranged from 8.2 to 13.3 m3 PMH-1, and cost from approximately 20 to 30 € m-3. The automated system did achieve a significantly higher productivity, but differences declined with extraction distance. When that was combined with the slightly higher cost for the automated system, the automated system was more cost effective on extraction distances less than 200 m, and the manual system on longer distances.

Download PDF here. DOI: http://afrjournal.org/index.php/afr/article/view/1883

2021 Skyline tension and dynamic loading for cable yarding comparing conventional single-hitch versus horizontal double-hitch suspension carriages

Spinelli R., Magagnotti N., Cosola, G., Grigolato, S., Marchi L., Rosario Proto A., Labelle, E.R., Visser R. & Erber, G.

“Skyline tension and dynamic loading for cable yarding comparing conventional single-hitch versus horizontal double-hitch suspension carriages”

International Journal of Forest Engineering, 26 April, 2021

Abstract: Wire rope used in cable logging, where a series of cables facilitate the extraction of timber on steep terrain, experiences high tensions that must be managed to ensure safety. Innovations change practices over time and double-hitch carriages, which allow trees to be extracted horizontally, are a recent example. This makes it feasible to harvest across terrain with limited deflection, increases the recovery of biomass, and potentially reduces high-dynamic load events associated with ground contact. In this study, a standard single-hitch carriage was compared against a new double-hitch carriage under controlled conditions. Tension was measured continuously and specific elements, such as tension when the carriage was at midspan, maximum tension at breakout and inhaul, and magnitude of cyclic tension during inhaul were identified, measured and compared against payload. While payload was similar in the treatments, the additional weight of the double-hitch carriage resulted in higher skyline tensions. In both treatments, payload and skyline tension when the carriage was at midspan were strongly correlated. Cyclic tension was reduced by the double-hitch carriage system. While a number of unique high-dynamic loads were identified that were not part of the normal extraction, they represented only 6% of the cycles and the maximum tension was similar to that experienced during break-out and inhaul. This study increased the understanding of skyline tension during logging operations and the effect of carriage type. It showed that, though tension often exceeds the safe working load of the cable, it does not exceed the endurance limit for a well-designed and operated system.

Download PDF HERE.

2021 Tree marking versus tree selection by harvester operator: are there any differences in the development of thinned Norway spruce forests?

Abstract: In Europe, Norway spruce forests are facing challenges due to climate change. One possible adaptive option is to enhance the resilience of forests by thinning. Usually, thinning requires two working steps: (i) tree marking by a forest manager and (ii) the harvesting operation. Since the typical tree selection procedure by forest managers is expensive and time consuming, the integration of the tree selection process in the harvesting operation is of high interest. In this paper, we examined four tree selection methods on 21 experimental plots located within eight Norway spruce stands and assessed their impact on the future stand development. The future stand development by tree selection methods was examined by means of a simulation study using the tree growth model MOSES (MOdeling Stand rESponse). The selection methods were (i) tree selection by forest managers, (ii) tree selection by the harvester operator as part of a fully mechanized harvesting system. Since we used the tree growth model MOSES, we additionally employed (iii) a random tree selection process implemented in MOSES, and (iv) a control simulation assuming no thinning. The Norway spruce stands are located in Lower Austria. The results show that 70% of the trees selected by the forest managers were identical to those chosen by the harvester operator and thus no significant differences in the key stand parameters after a 50-year simulation is detectable. Our study suggests that the tree selection for thinning by a trained harvester operator is a cost-efficient and fast method.

Download PDF HERE.

2021 The Effect of Yarding Technique on Yarding Productivity and Cost: Conventional Single-Hitch Suspension vs. Horizontal Double-Hitch Suspension

Spinelli R., Magagnotti N., Cosola G., Labelle E., Visser R., Erber G.

The Effect of Yarding Technique on Yarding Productivity and Cost: Conventional Single-Hitch Suspension vs. Horizontal Double-Hitch Suspension

Croatian Journal of Forest Engineering

Abstract

Cable yarding is a well establish technology for the extraction of timber in steep terrain. However, it is encumbered with relatively low productivity and high costs, and as such this technology needs to adapt and progress to remain viable. The development of biomass as a valuable by-product, and the availability of processors to support yarder operations, lend themselves to increasing the level of whole-tree extraction. Double-hitch carriages have been developed to allow for full suspension of whole-tree and tree-length material. This study compared a standard single-hitch to a double-hitch carriage under controlled conditions, namely in the same location using the same yarder with downhill extraction. As expected, the double-hitch carriage took longer to load up (+14%), but was able to achieve similar productivity (10–11 m3 per productive machine hour) through increased inhaul speed (+15%). The importance of this study is that it demonstrates both the physical and economic feasibility of moving to whole-tree extraction using the double-hitch type carriage for longer corridors, for settings with limited deflection, or areas with lower tolerance for soil disturbance.

Download PDF HERE.

2021 The relationship between volume increment and stand density in Norway spruce plantations

Micky Allen, Andreas Brunner, Clara Antón Fernández, Rasmus Astrup.

The relationship between volume increment and stand density in Norway spruce plantations

Forestry

Abstract

An understanding of the relationship between volume increment and stand density (basal area, stand density index, etc.) is of utmost importance for properly managing stand density to achieve specific management objectives. There are two main approaches to analyse growth–density relationships. The first relates volume increment to stand density through a basic relationship, which can vary with site productivity, age, and potentially incorporates treatment effects. The second is to relate the volume increment and density of thinned experimental plots relative to that of an unthinned experimental plot on the same site. Using a dataset of 229 thinned and unthinned experimental plots of Norway spruce, a growth model is developed describing the relationship between gross or net volume increment and basal area. The models indicate that gross volume increases with increasing basal area up to 50 m2 and thereafter becomes constant out to the maximum basal area. Alternatively, net volume increment was maximized at a basal area of 43 m2 and decreased with further increases in basal area. However, the models indicated a wide range where net volume increment was essentially constant, varying by less than 1 m3ha−1 year−1. An analysis of different thinning scenarios indicated that the relative relationship between volume increment and stand density was dynamic and changed over the course of a rotation.

The full publication can be viewed HERE.

2021 Applications of DEA and SFA in benchmarking studies in forestry: state-of-the-art and future directions

Niels Strange; Peter Bogetoft; Giovanna Ottaviani Aalmo; Bruce Talbot; Anders Holm Holt & Rasmus Astrup.

Applications of DEA and SFA in benchmarking studies in forestry: state-of-the-art and future directions

International Journal of Forest Engineering

Abstract

The forestry sector is constantly looking for ways for making data-driven decisions and improving efficiency. The application of Data Envelopment Analysis (DEA) and Stochastic Frontier Analysis (SFA) allow the users to go beyond looking at simple key performance indicators. Benchmarking is one of the most common tools in business for improving efficiency and competitiveness. This study searched for benchmarking studies in Web of Science until December 2020. It reviewed 56 benchmarking studies in forestry and discusses the potential advantages of using benchmarking in forestry. More than 80% of the studies apply DEA. This review found that almost half of the benchmarking studies in forestry have attempted to estimate the efficiency of forest management organizations at regional scale, mostly being public or state-owned forest districts. A bit more than one-third of the studies have focused on benchmarking forest industries and one-fifth, benchmarking of forest operations. Forest management organizations mainly applied benchmarking for internal comparison and forest industries entirely focused on competitive benchmarking. Surprisingly, in most cases the studies do not necessarily overlap geographically with forest rich countries (e.g., Russian Federation or Brazil). A number of studies address multiple criteria. The future potential for applying automatic data transfer from harvest machines to interactive benchmarking systems are discussed. Finally, the paper discusses the advantages and weaknesses of benchmarking and future research on improving usefulness and usability of benchmarking in forest businesses.

The full scientific paper can be view HERE.

2020

2020 Effect of a traction-assist winch on wheel slippage and machine induced soil disturbance in flat terrain

M. Schönauer, T. Holzfeind, S. Hoffmann, F. Holzleitner, B. Hinte & D. Jaeger

“Effect of a traction-assist winch on wheel slippage and machine induced soil disturbance in flat terrain”

International Journal of Forest Engineering (Nov 2020)

Abstract: Recently, forest operations are facing unfavorable climatic conditions more frequently. In Central Europe, machine trafficability and induced soil disturbances are negatively affected by periods of high precipitation and less intensive frost during ground-based harvesting operations. Winch-assist technology is assumed to reduce soil disturbance by forest machines in steep terrain. Still, the potential positive effects of winches to assist traction of forest machines in flat terrain have rarely been surveyed. In this study, a field trial was conducted in flat terrain (slope here

2020 The mental workload of harvester operators working in steep terrain conditions

Grzegorz Szewczyk , Raffaele Spinelli , Natascia Magagnotti , Paweł Tylek , Janusz M. Sowa, Piotr Rudy and Dominika Gaj-Gielarowiec

”The mental workload of harvester operators working in steep terrain conditions’‘

Silva Fennica (July 2020)

Abstract: The use of modern multi-functional forestry machines has already been associated with central nervous system fatigue induced by high mental workload. As these machines are being used under increasingly difficult terrain conditions, further knowledge is required on the expected aggravation of operators’ mental workload, so that suitable work/rest schedules can be developed. Within such a context, the aim of this study was to gauge aggravations of mental workload derived from increasing slope gradient. Measurements of eye activity were obtained from a representative harvester operator working in corridors with the following mean inclinations: 9%, 23% and 47%. The duration, frequency and trajectory of eye movements were used to determine the harvester operator’s mental workload, on the assumption that worsening work conditions would be reflected by increased eyeball activity.

The number of fixations during the performance of all tasks increased with the increasing slope gradient. Similarly, fixation duration increased with slope gradient. The mean duration of saccades when working on a 23% slope was 5% shorter compared to work under a 9% gradient. A further significant shortening of saccade duration (~22%) occurred when working on a 47% slope. The good match between eye activity cycles and work cycles, visible especially on steep slopes, indicates that mental workload is related to work conditions. Overall, operating a forest harvester on steep slopes results in a greatly increased mental workload and calls for suitable rest schedules.

Download the PDF here.

2020 The Effect of New Silvicultural Trends on Mental Workload of Harvester Operators

Raffaele Spinelli, Natascia Magagnotti, Eric R. Labelle

”The Effect of New Silvicultural Trends on Mental Workload of Harvester Operators’‘

Abstract: Close-to-nature (CTN) forestry offers many advantages, but makes management more complex and generally results in lower harvesting productivity and higher harvesting cost. While the higher harvesting cost of CTN is widely acknowledged, few ever consider the potential impact on operator workload, as the harvesting task becomes more complex.

This study aimed to determine the mental workload of harvester operators under two silvicultural regimes: »pure conifer« stand and »mixwood« stand. In total, 13 harvester operators with varying experience levels were monitored for work performance and mental workload when operating a harvester simulator in two virtual stands designed according to the above-mentioned silvicultural regimes.

Mental workload was assessed using the NASA Task Load Index (NASA-TLX) interview method and heart rate variability measurements, during two 30-minute test sessions performed in the »pure conifer« and the »mixwood« stand, respectively. As expected, operating in a more diversified »mixwood« stand resulted in a marked productivity loss, estimated between 40 and 57%. The study also confirmed the increased aggravation of mental demand, effort and frustration experienced by the operators when passing from the »pure conifer« stand to the »mixwood« stand.

Such increase in mental workload was independent of the age and experience of the operators. Results can be used to paint a more holistic picture of CTN forestry and its implications for harvester operators. Besides increasing the number of subjects being monitored, future studies should focus on live forest operations.

Download the PDF here.

2020 New models developed on the cutting duration, fuel consumption for CTL single grip harvester sawing units

Robert Prinz · Kari Väätäinen · Johanna Routa

”Cutting duration and performance parameters of a harvester’s sawing unit under real working conditions’‘

European Journal of Forest Research (September 2020)

Abstract: Amongst all the working elements of single grip harvesters, the working elements of felling and processing play an important role within the cut-to-length (CTL) harvester’s working phases. This includes the felling cutting and cross-cutting of stems within the felling and processing operation. The detailed investigation of such individual machine activities may help to analyse and improve the performance of forest machines. The objective of this study was to investigate the cutting duration and other performance parameters, including the fuel consumption, of a CTL harvester’s sawing unit under real working conditions.

Detailed information on the felling cutting and cross-cutting performance was collected at short intervals using CAN bus data of two single grip harvesters in final felling from two different sites in Eastern Finland. As a result, models for effective time consumption in the work phase of cutting as a function of stem size were developed, both for felling cutting and cross-cutting. Felling cutting and cross-cutting durations were somewhat identical until the cutting diameters of 400–450 mm, depending on the site. Thereafter, the cutting time difference increased and was higher in felling cutting. At the site with large diameters of 550–650 mm, the difference varied between 15% and 28%, between the comparisons of formulae. In addition, other performance parameters, including the respective fuel consumption of this working phase, were part of the study.

The study revealed a higher hourly based fuel consumption for the entire guide bar movement time compared to the pure cutting time in cross-cutting with stem diameters below 400 mm. Detailed knowledge of the performance of the sawing unit’s activities might help the planning process of future studies, as well as support the future development of efficient and intelligent machinery.

Download the PDF here.

2020 Timber extraction by cable yarding on flat and wet terrain: a survey of cable yarder manufacturer’s experience

G. Erber (BOKU Vienna, Austria) & R. Spinelli (CNR, Italy)

“Timber extraction by cable yarding on flat and wet terrain: a survey of cable yarder manufacturer’s experience”

Silva Fennica 54 (2), article 10211, 19 p.

Cable yarding is a general solution for load handling on sites not accessible to ground-based machinery, and is typically associated with steep terrain. On flat terrain, such conditions can primarily be found on soft or wet soils, most frequently encountered in Central and Northern European countries. Today, changed environmental and market conditions may offer an unprecedented opportunity to the actual implementation of cable yarding on flat terrain in commercial operations.

The study goal was to collect cable yarder manufacturers experience regarding the use and adaption of cable yarding technology on flat terrain. European manufacturers of cable yarding technology were interviewed about customer experience, particular challenges, adaptation potential, future potential and main hurdles for the expansion of cable yarding on flat terrain. Almost all manufacturers have received requests for flat-terrain yarding technology solutions, primarily from Germany. Temporal or permanent inaccessibility, regulatory or environmental reasons were the most frequent motivation for considering cable yarding technology. Installation was considered particularly challenging (clearance, stable anchoring). Potential adaptations included higher towers, artificial anchors, mechanized bunching before extraction and un-guyed yarder-systems.

An artificial, highly mobile, self-anchoring tail spar was considered the most useful adaptation. While concerned about limited profitability and qualified labour shortage, most manufacturers demonstrated a positive or neutral view concerning the expansion of cable yarding on flat terrain. However, cable yarding is not considered to be cost-competitive wherever ground-based systems can be employed and cable yarding is not subsidized.

Download PDF of here: Erber & Spinelli (2020)

2020 Efficiency drivers in harvesting operations in mixed Boreal stands: a Norwegian case study

Ottaviani Aalmo, G., Jan Kerstens, P., Belbo H., Bogetoft P., Talbot B., & Strange, N.

Efficiency drivers in harvesting operations in mixed Boreal stands: a Norwegian case study

International Journal of Forest Engineering, 17 June, 2020

Abstract: This paper uses Data Envelopment Analysis (DEA) to evaluate how the technical efficiency of forest harvesting operations is influenced by terrain conditions and forest attributes, in addition to exploring the existence of other influencing factors. To this end, 643 shift-level observations of harvesting opera- tions on 253 distinct harvested sites were used. The aim of this study is to highlight the harvester’s ability to maximize the outputs, represented by the number of assortments for various tree species, given inputs such as harvest volume, harvest time for various tree species, and distance traveled by the harvester. Operational environment variables such as harvest, or decision-making unit (DMU) size, shape, and terrain characteristics were included. We found large variations in efficiency scores, and that inefficient harvest operations could theoretically be improved by reducing input by up to ca. 80%. A second stage regression estimation was applied to identify which factors significantly affected inefficiency. It was found that the inefficiency decreases with increasing stem-volume for pine and broadleaves, increasing stand density, and increasing share of pulpwood and non-marketable timber, while it increases with the number of logs produced per tree (in broadleaves). Inefficiency increases also with an increasing ratio of actual travel distance to minimal travel distance. The study shows how adopting DEA methods in forest operations might be used in combining efficiency analysis and environmental factors, by identifying and measuring inefficiency due to, for example, difficult terrain.

Download the PDF HERE.

2019

2019 Productivity in Mechanizing Early Tending in Spruce Seedling Stands

Routa Johanna (LUKE), Nuutinen Yrjö and Asikainen Antti

Croatian Journal of Forest Engineering 2019, volume 41, issue 1, 10 pp.

Abstract: According to National Forest Inventory data, there is an urgent need for tending seedling stands of at least 700,000 ha and a need for 1 million ha in the next few years in Finland. The motivation for forest owners to conduct pre-commercial silvicultural operations is low due to the associated high costs. Especially the costs of tending and clearing operations after the regeneration of the stand have been increasing. In addition, the availability of labor is a restricting factor due to the high seasonality of silvicultural works.

In the 2000s, several solutions for the mechanization of tending have been proposed. These are based on the use of harvester or a forwarder as a base machine. Typically, light weight base machines are favored to reduce the hourly cost of operations and the impacts on the remaining seedlings. There have been challenges with the high speed of the cutting device, which increases the risk of damages to the head and the ignition of forest fires when the circular saw or chain hits stones, for example. In addition, the chain can become dislocated due to bending forces caused by stumps.

Cutlink has presented a low RPM solution based on rotating cone-shaped shears that cut 50–100 cm wide corridors between and around seedlings. In this study, the productivity of mechanized tending with Cutlink´s device compared to manual tending was evaluated in spruce seedling stands in central Finland. The productivity, fuel consumption and quality of the seedling stand after the operation were measured. In early tending, the productivity of motor manual tending was notably better than when using the Cutlink device. Crucial factors for the competitiveness of a mechanized alternative include the annual working hours and finding suitable working areas for the machine. Additional work for the device and base machine can also be found in the clearing of forest road sides.

To read the full article go to the journal website or download the PDF!

2019 Spatial distribution of the potential forest biomass availability in Europe

Pieter Johannes Verkerk, Joanne Brighid Fitzgerald, Pawan Datta, Matthias Dees, Geerten Martijn Hengeveld, Marcus Lindner and Sergey Zudin

Forest Ecosystems 2019,

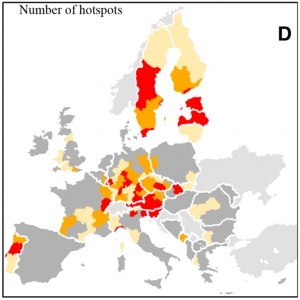

Background: European forests are considered a crucial resource for supplying biomass to a growing bio-economy in Europe. This study aimed to assess the potential availability of forest biomass from European forests and its spatial distribution. We tried to answer the questions (i) how is the potential forest biomass availability spatially distributed across Europe and (ii) where are hotspots of potential forest biomass availability located?

Methods: The spatial distribution of woody biomass potentials was assessed for 2020 for stem wood, residues (branches and harvest losses) and stumps for 39 European countries. Using the European Forest Information SCENario (EFISCEN) model and international forest statistics, we estimated the theoretical amount of biomass that could be available based on the current and future development of the forest age-structure, growing stock and increment and forest management regimes. We combined these estimates with a set of environmental (site productivity, soil and water protection and biodiversity protection) and technical (recovery rate, soil bearing capacity) constraints, which reduced the amount of woody biomass that could potentially be available. We mapped the potential biomass availability at the level of administrative units and at the 10 km × 10 km grid level to gain insight into the spatial distribution of the woody biomass potentials.

Results: According to our results, the total availability of forest biomass ranges between 357 and 551 Tg dry matter per year. The largest potential supply of woody biomass per unit of land can be found in northern Europe (southern Finland and Sweden, Estonia and Latvia), central Europe (Austria, Czech Republic, and southern Germany), Slovenia, southwest France and Portugal. However, large parts of these potentials are already used to produce materials and energy. The distribution of biomass potentials that are currently unused only partially coincides with regions that currently have high levels of wood production.

Conclusions: Our study shows how the forest biomass potentials are spatially distributed across the European continent, thereby providing insight into where policies could focus on an increase of the supply of woody biomass from forests. Future research on potential biomass availability from European forests should also consider to what extent forest owners would be willing to mobilise additional biomass from their forests and at what costs the estimated potentials could be mobilised.

Download pdf

Data is also available on Zenodo.

Figure 4d: Biomass hotspots per regio

2019 Decreasing the Fuel Consumption and CO2 Emissions of Excavator-Based Harvesters with a Machine Control System

Raffaele Spinelli and Angelo Conrado de Arruda Moura

Forests 2019,

Compared with purpose-built units, excavator-based harvesters offer many advantages, but they also face one main limitation: a much higher fuel consumption, which also results in higher CO2 emission levels. The fuel efficiency of excavator-based harvesters can be increased by a better interface between the excavator and the harvester head. This study aimed to determine the performance of a new adaptation kit, specifically designed to improve the communication between these two components. The new kit offers real-time adjustment between the power demand of the harvester head and the power output of the excavator, which should help reducing fuel consumption while stabilizing hydraulic fluid temperature. The test was conducted on 53 excavator-based harvesters purchased and managed by a large Brazilian company. Time use, fuel consumption and production were monitored continuously for one full month, before and after installation of the kit. Overall, the study covered 40,000 h of work, during which the harvesters cut, processed, and debarked 4.5 million trees, or 650,000m3 of wood, under bark. Fuel consumption amounted to 900,000 liters. After installing the adaptation kit, productivity increased 6%, while fuel consumption per hour decreased 3.5%. Fuel consumption and CO2 emissions per product unit decreased 10%, as an average. The effect of random variability typical of an observational study prevented formulating an accurate figure for the amount of fuel that can be saved by installing the adaptation kit. Yet, one may confidently state that, in most cases, installing the kit results in a reduction of fuel use, and that such reduction is most often in the range from -10 to -20% on a per m3 basis.

2019 Effects of intensified silviculture on timber production and its economic profitability in boreal Norway spruce and Scots pine stands under changing climatic conditions

J. Routa, A. Kilpeläinen, V.-P. Ikonen, A. Asikainen, A. Venäläinen and H. Peltola

The aim of this study was to examine how intensified silviculture affects timber production (sawlogs and pulp- wood) and its economic profitability (net present value [NPV], with 2 per cent interest rate) based on forest ecosystem model simulations. The study was conducted on Norway spruce and Scots pine stands located on medium-fertile upland forest sites under middle boreal conditions in Finland, under current climate and minor climate change (the RCP2.6 forcing scenario). In intensified silviculture, improved regeneration materials were used, with 10–20 per cent higher growth than the unimproved materials, and/or nitrogen (N) fertilization of 150 kg ha−1, once or twice during a rotation of 50–70 years. Compared to the baseline management regime, the use of improved seedlings, alone or together with N fertilization, increased timber production by up to 26–28 per cent and the NPV by up to 32–60 per cent over rotation lengths of 60–70 years, regardless of tree species (although more in spruce) or climate applied. The use of improved seedlings affected timber yield and NPV more than N fertilization. Minor climate change also increased these outcomes in Scots pine, but not in Norway spruce.

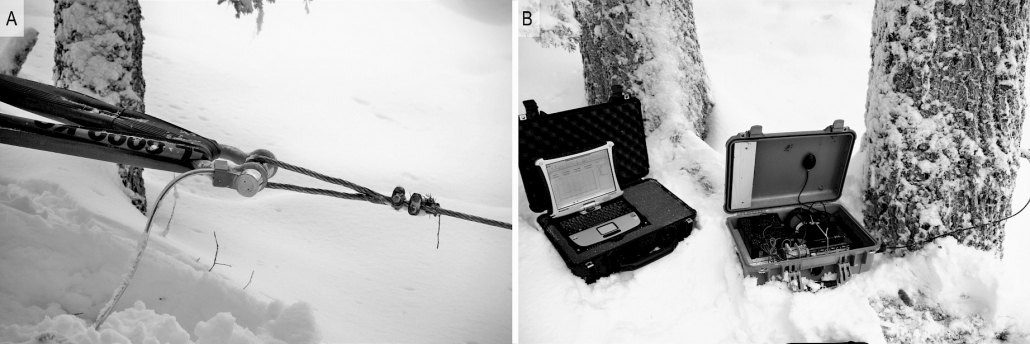

2019 Assessing Cable Tensile Forces and Machine Tilt of Winch-Assisted Forwarders on Steep Terrain under Real Working Conditions

T. Holzfeind, C. Kanzian, K. Stampfer, F. Holzleitner

Winch-assisted forwarders are now commonly accepted as an innovative alternative for extracting wood on challenging terrain. In order to assess safety risks, it is necessary to know the tensile forces in the steel wire rope and their interaction with the machine tilt under real working conditions. In this study, the tensile force and the machine tilt of two winch-assisted forwarders (John Deere 1210E and Komatsu 840TX) were observed for about 15 work hours without delays on two different stands in Austria. The tensile force data and the machine tilt data were separated by work elements. The mean tensile force ranged from 18.1 kN for unloading up to 56.8 kN for loading activities. During the measurements, the cable tensile force exceeded 50% of the minimum breaking strength (MBS) only twice. The maximum observed tensile force was 174.5 kN or 82.7% of the MBS, respectively, which led to a failure of the steel cable. For the machine tilt, a maximum of 80% was measured during loading and driving during loading. John Deere 1210E was operated 31% of the productive work time above the manufacturers tilt limit. For Komatsu 840TX, the manufacturers’ maximum tilt limit was exceeded only twice. The study also showed that peaks with an amplitude of up to 50 kN can occur within a few centiseconds, which highlights the need of high measurement rates, when measuring cable tensile force of winch-assisted machinery. The detailed analysis of the peaks showed that 90% of the pit-to-peak amplitudes ≥20 kN occurred during driving activities. Only 10% of pit-to-peak amplitudes ≥20 kN were measured during loading activities, although loading took about 43.5% of the productive work time. As such, the study results confirm that amplitudes of peaks in tensile force, and hence safety risks, are significantly higher during driving than during loading.

Fig. 1 Load shackle mounted between anchor tree and steel cable of a winch-assisted forwarder (A), and measurement equipment for ob-serving tensile force (B)

2018

2018 An operational UAV-based approach for stand-level assessment of soil disturbance after forest harvesting

Bruce Talbot, Johannes Rahlf, Rasmus Astrup

Scandinavian Journal of Forest Research 2018,

The effectiveness of generating virtual transects on unmanned aerial vehicle-derived orthomosaics was evaluated in estimating the extent of soil disturbance by severity class. Combinations of 4 transect lengths (5–50 m) and five sampling intensities (1–20 transects per ha) were used in assessing traffic intensity and the severity of soil disturbance on six post-harvest, cut-to-length (CTL) clearfell sites. In total, 15% of the 33 ha studied showed some trace of vehicle traffic. Of this, 63% of was categorized as light (no visible surface disturbance). Traffic intensity varied from 787 to 1256 m ha−1, with a weighted mean of 956 m ha−1, approximately twice the geometrical minimum achievable with CTL technology under perfect conditions. An overall weighted mean of 4.7% of the total site area was compromised by severe rutting. A high sampling intensity, increasing with decreasing incidence of soil disturbance, is required if mean estimation error is to be kept below 20%. The paper presents a methodology that can be generally applied in forest management or in similar land-use evaluations.

2018 Modifying the settings of CTL timber harvesting machines to reduce fuel consumption and CO2 emissions

Robert Prinz, Raffaele Spinelli, Natascia Magagnotti, Johanna Routa, Antti Asikainen

Journal of Cleaner Production 2018,

The objectives of this study were to examine the possibility of reducing the fuel consumption and CO2 emissions of harvesters during cut-to-length operations by applying various technical settings to the machine through the machine’s own software package. The adjustment of machine settings had an effect on the fuel consumption per unit product (l m−3) and can reduce the fuel consumption and CO2 emissions in cut-to-length harvesting operations. The main factor significantly affecting both fuel consumption and productivity was stem size. The study involved three cut-to-length machines operating in thinning with comparable stand environment and silvicultural prescriptions.

The novelty of this work is in exploring the fuel saving potential of simple adjustments of machine settings in cut-to-length harvesting machines. Such adjustments have an impact on fuel efficiency and may reduce fuel consumption and CO2 emissions in cut-to-length harvesting operations. This work may result in a reduction of energy consumption and environmental pollution, thereby contributing to cleaner production. This study bridges the gaps between research, development and implementation: it offers practical solutions that may affect manufacturers as well as practitioners and entrepreneurs in the field. The outcome of this study may result in innovative technology development with less impact on the environment.

Figure 1: The machines studied in the experiment, upper-left the Ponsse Beaver, upper-right the Ponsse ScorpionKing, below the Ponsse Ergo.

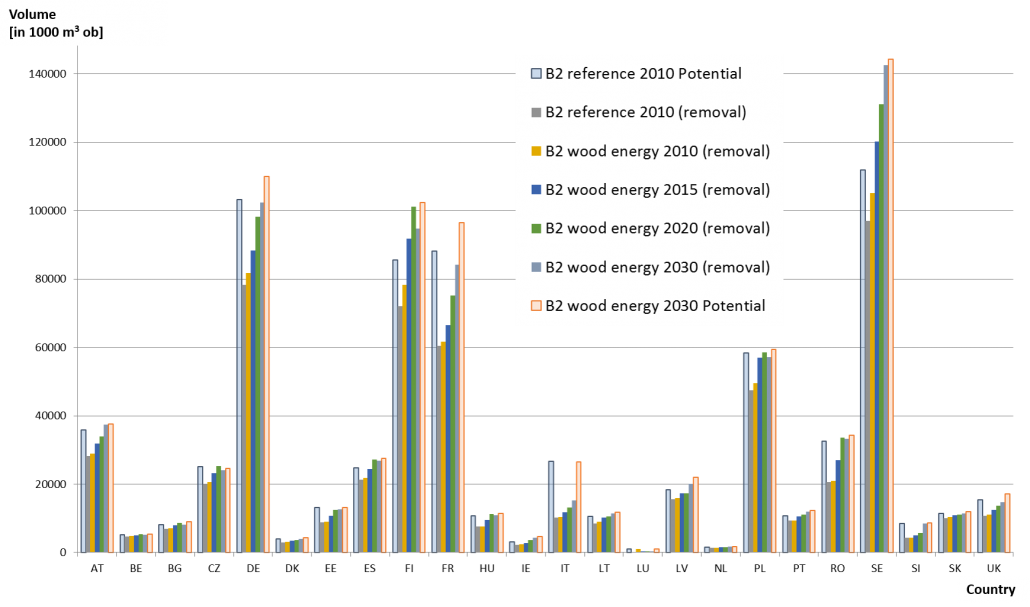

2018 Sustainability impacts of increased forest biomass feedstock supply – a comparative assessment of technological solutions

Diana Tuomasjukka, Salvatore Martire, Marcus Lindner, Dimitris Athanassiadis, Martin Kühmaier, Jan Tumajer, Martijn Vis, Raffaele Spinelli, Matthias Dees, Robert Prinz, Johanna Routa & Antti Asikainen

International Journal of Forest Engineering 2018,

Sustainably managed forests provide renewable raw material that can be used for primary/secondary conversion products and as biomass for energy generation. The potentially available amounts of timber, which are still lower than annual increments, have been published earlier. Access to this timber can be challenging for small-dimensioned assortments; however, technologically improved value chains can make them accessible while fulfilling economic and environment criteria. This paper evaluates the economic, environmental and social sustainability impacts of making the potentially available timber available with current and technologically improved value chains. This paper focuses on increasing the biomass feedstock supply for energy generation. Quantified impact assessments show which improvements – in terms of costs, employment, fuel and energy use, and reduced greenhouse gas emissions – can be expected if better mechanized machines are provided. Using three different methods – Sustainability Impacts Assessment (SIA), Life Cycle Assessment (LCA), and Emission Saving Criteria (ESC) – we calculated current and innovative machine solutions in terms of fuel use, energy use, and greenhouse gas emissions, to quantify the impact of the technology choice and also the effect of the choice of assessment method. Absolute stand-alone values can be misleading in analyses, and the use of different impact calculation approaches in parallel is clarifying the limits of using LCA-based approaches. The ESC has been discussed for the recast of the Renewable Energy Directive. Potential EU-wide results are presented.

Figure 1: Comparison of 2010 reference and 2030 wood energy forest potential (pale bars), against B2 reference 2010 removal (solid bar) as well as B2 wood energy removals for 2010, 2015, 2020, 2030 (solid bars). The removals do not include volumes from pre-commercial thinning. Potentials do include volumes from pre- commercial thinning.

2017

2017 Applications for Remote and Proximal Sensing for Improved Precision in Forest Operations (Review)

Bruce Talbot, Marek Pierzchała, Rasmus Astrup

Croatian Journal of Forestry Engineering (CROJFE) 38(2017)2; 327-336

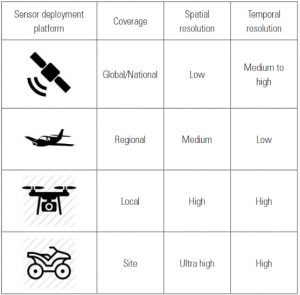

This paper provides an overview of recent developments in remote and proximal sensing technologies and their basic applicability to various aspects of forest operations. It categorises these applications according to the technologies used and considers their deployment platform in terms of their being space-, airborne or terrestrial. For each combination of technology and application, a brief review of the state-of-the-art has been described from the literature, ranging from the measurement of forests and single trees, the derivation of landscape scale terrain models down to micro-topographic soil disturbance modelling, through infrastructure planning, construction and maintenance, to forest accessibility with ground and cable based harvesting systems. The review then goes on to discuss how these technologies and applications contribute to reducing impacts on forest soils, cultural heritage sites and other areas of special value or interest, after which sensors and methods necessary in autonomous navigation and the use of computer vision on forest machines are discussed.

General characterisation of sensor deployment platform to spatial coverage and temporal resolution (adapted from Pierzchała 2017)

2017 Value Retention, Service Life, Use Intensity and Long-Term Productivity of Wood Chippers as Obtained from Contractor Records

Raffaele Spinelli, Lars Eliasson, Natascia Magagnotti

Forests 2017, 8(12), 503

Acknowledging the absence of up-to-date empirical data on the value retention, service life and annual use of chipping machinery, in 2017 the authors surveyed the records kept by 50 contractors offering biomass chipping services. The machine fleet and operations in this survey could be taken as representative for most of Europe, where the biomass sector is well established and is facing further expansion. Data collection included the whole chipping unit, comprised of chipper, carrier and loader. Manually-fed units were excluded from the survey. The data pointed at a service life up to and exceeding 10,000 h and 10 years, which relieved any concerns about poor durability. Value retention was good, and may exceed that of other mainstream forestry equipment. Engine power was the main explanatory variable in any models to predict purchase price and productivity. The effect of this variable could explain most of the variability (>80%) in the purchase price and productivity data. Results also pointed at the essential equivalence in price and productivity between PTO-driven (i.e., tractor powered) and independent-engine chippers, once differences in engine power are accounted for. However, the distribution of purchase price between different components of the chipping unit was different between the two unit types, with the chipper accounting for a larger proportion of the total investment in independent-engine units. Machine power was also different, with most PTO-driven units being significantly smaller than independent-engine units, due to the limitations of existing tractors. Furthermore, half of the carriers assigned to a PTO-driven unit were subject to flexible use, i.e., they were not solely used for chipping work.

2017 A Robust Productivity Model for Grapple Yarding in Fast-Growing Tree Plantations

Riaan Engelbrecht, Andrew McEwan, Raffaele Spinelli

Forests 2017, 8(10), 396

New techniques have recently appeared that can extend the advantages of grapple yarding to fast-growing plantations. The most promising technique consists of an excavator-base un-guyed yarder equipped with new radio-controlled grapple carriages, fed by another excavator stationed on the cut-over. This system is very productive, avoids in-stand traffic, and removes operators from positions of high risk. This paper presents the results of a long-term study conducted on 12 different teams equipped with the new technology, operating in the fast-growing black wattle (Acacia mangium Willd) plantations of Sarawak, Malaysia. Data were collected continuously for almost 8 months and represented 555 shifts, or over 55,000 cycles—each recorded individually. Production, utilization, and machine availability were estimated, respectively at: 63 m3 per productive machine hour (excluding all delays), 63% and 93%. Regression analysis of experimental data yielded a strong productivity forecast model that was highly significant, accounted for 50% of the total variability in the dataset and was validated with a non-significant error estimated at less than 1%. The figures reported in this study are especially robust, because they were obtained from a long-term study that covered multiple teams and accumulated an exceptionally large number of observations.